Continuous improvement keeps Hazera Seeds in the global top

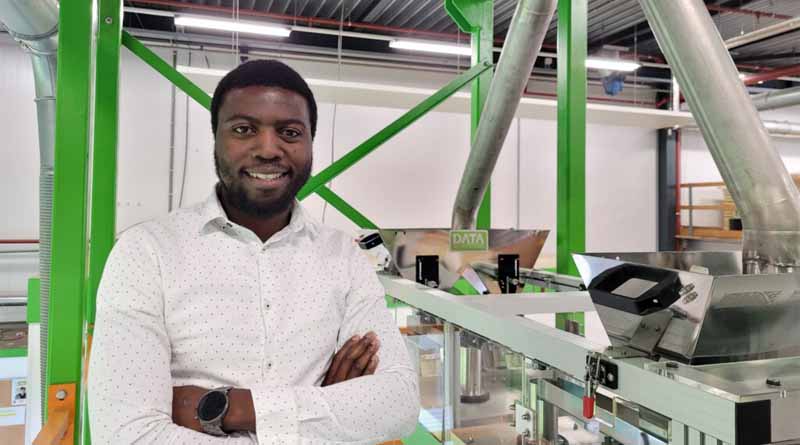

13 April 2023, US: Hazera is committed to developing high-quality seeds that allow communities to flourish. To do that, Hazera focuses on continually improving its operational excellence in research, production, processing and quality for both customers and employees. “We deliver the best to our customers, and we want to keep it that way”, says Tyrrel Chisenga, Seed technologist. “We put in a lot of effort, but there is always room for improvement.”

“We breed for new varieties, and multiply seeds for growers and farmers alike”, Tyrrel explains. “After production, we perform extensive quality control tests to confirm that our seeds meet the commercial quality standards. Based on the various tests that we execute, we initiate processing activities to ensure that we deliver quality. We also take care of physiological enhancement to ensure seedling vigour and establishment even under sub-optimal conditions. Our efforts are to make sure the seeds that our farmers sow and nurture into a crop, grow and eventually end up as delicious vegetables in supermarkets across the world.”

Quality control and Seed technology

Quality control and Seed technology are an indispensable component for Hazera when it comes to making sure we deliver the best quality. “Nature comes with its challenges and when we encounter challenges that may compromise the final product quality after production we initiate research into the causes and solutions”, says Tyrrel. “Such research may encompass physiological, physical, health, genetic aspects of the seeds or efficiency of processes. Everything we do is to ensure optimum quality for our customers.”

On top of the game

Even though Hazera adheres to the commercial quality standards and guarantees quality, there is always room for improvement, Tyrrel finds. Hazera invests in continually improving seed quality. “These investments include machinery for seed enhancement, automation of processes and the use of imaging systems for better inline decision making. Additionally, there are improved protocols with reduced lead times. We introduced the Lean management system in our processing plants. We created a work environment that allows the smooth and fast flow of processes and at the same time reduces work load. This allows us to cater to the needs of our customers in a brief period.”

For Hazera, its employees are on the same pedestal as the customers. Tyrrel: “The most important thing for the welfare of our employees is to make sure that their work remains interesting and safe. That is why we made a new tomato pelleting formulation that is safer for our employees to apply. It also results in improved sowability and seedling performance.”

(For Latest Agriculture News & Updates, follow Krishak Jagat on Google News)